I decided to have a go at sourcing knobs again. This time I've tried to find factories or wholesellers, but it is damn hard. The problem it seems, is that I'm looking for the rarest element known to man - black knobs without a pointer and with D-shaft instead of knurled shaft.

I've been able to get in touch with a couple of vendors and one factory in the UK so far.

Here is an overview:

Cliff Electronic Components Ltd

They produce and sell a large range of knobs, many of which are white labeled and sold by RS Components (RS Pro brand), Conrad and similar.

Unfortunately, noone stocks pointerless knobs, much less D-shaft versions.

Example of what IS available

https://www.conrad.de/de/p/cliff-fc7233-drehknopf-schwarz-x-h-30-mm-x-16-mm-1-st-704510.html

|

| From Conrad |

|

| From RS |

https://www.cliffuk.co.uk/products/knobs/rotary.htm#kmr12

After contacting sales at Cliff I got this:

It looks like I need the US version of D-shaft for my encoders.There are two problems - I can't find a small (10mm in diameter) version of the pots, and the MOQ per type is 2000. The 15mm one would cost me GBP 0.526 / each, the 25mm GBP 1.332 / each and the 30mm GBP 0.963.

PMDWay

I DID find a knob on globalsources earlier, but the vendor is no longer on there:

Action Hardware

https://actionhardware.co.uk keeps popping up in my image searches, particularly two knobs:

Unfortunately, both are unavailable. They are however willing to help me do custom orders. The MOQ is 1000 and approximate prices between GBP 0.65 and GBP 1.50 /pce.

Ian at Action hardware says they stock parts similar to what I'm looking for and suggests KM-2100 and KM-2600:

This knob looks perfect, so does this, but there are no drawings to tell me the sizes. (KM-2100 is 14mm according to Ian, but KM-2500 remains a mystery)

Aliexpress

All the knobs I've found so far has been from Ali. Here is a list of what I've bought that looks good:

JU-HIVOR

https://www.aliexpress.com/item/32843175222.html

These are perfect - but unfortunately knurled shaft as always. I've bought 100 of these and they are my fallback solution if I can't find anything. 17mm in dia and 14 mm high. JU-HIVOR could not help me find anything.

DIKAVS

I was able to buy a nice knob here, but it is too low and now it's unavailable too.

These are the best large knobs I've found - I snagged four 32mm and one 30mm ones, the last one they had. Knurled shaft of course, and nothing has appeared since. DIKAVS never got back to me when I asked for help either.

Luyu Store

https://www.aliexpress.com/item/4001093464710.html

Luyu has some reeeally good looking knobs, 10.2 x 16mm. Unfortunately, they are for switches and have 3.2mm square holes. It is possible to drill an 8mm hole and 3D print a D-shaft insert which is my fallback solution for smaller pots. Luyu did not get back to me when I tried contacting them.

Best Partner Mall

https://www.aliexpress.com/item/32952829517.html

These look great, but are too big for me and has that damn knurled shaft of course.

Best partner mall have a lot of great knobs and I've bought a few alternatives from them too:

https://www.aliexpress.com/item/4000900076410.html

These are super nice! A bit costly but solid aluminum. If they had the same knobs in other sizes these would be my choice, even if they are quite expensive.https://www.aliexpress.com/item/32921539254.html

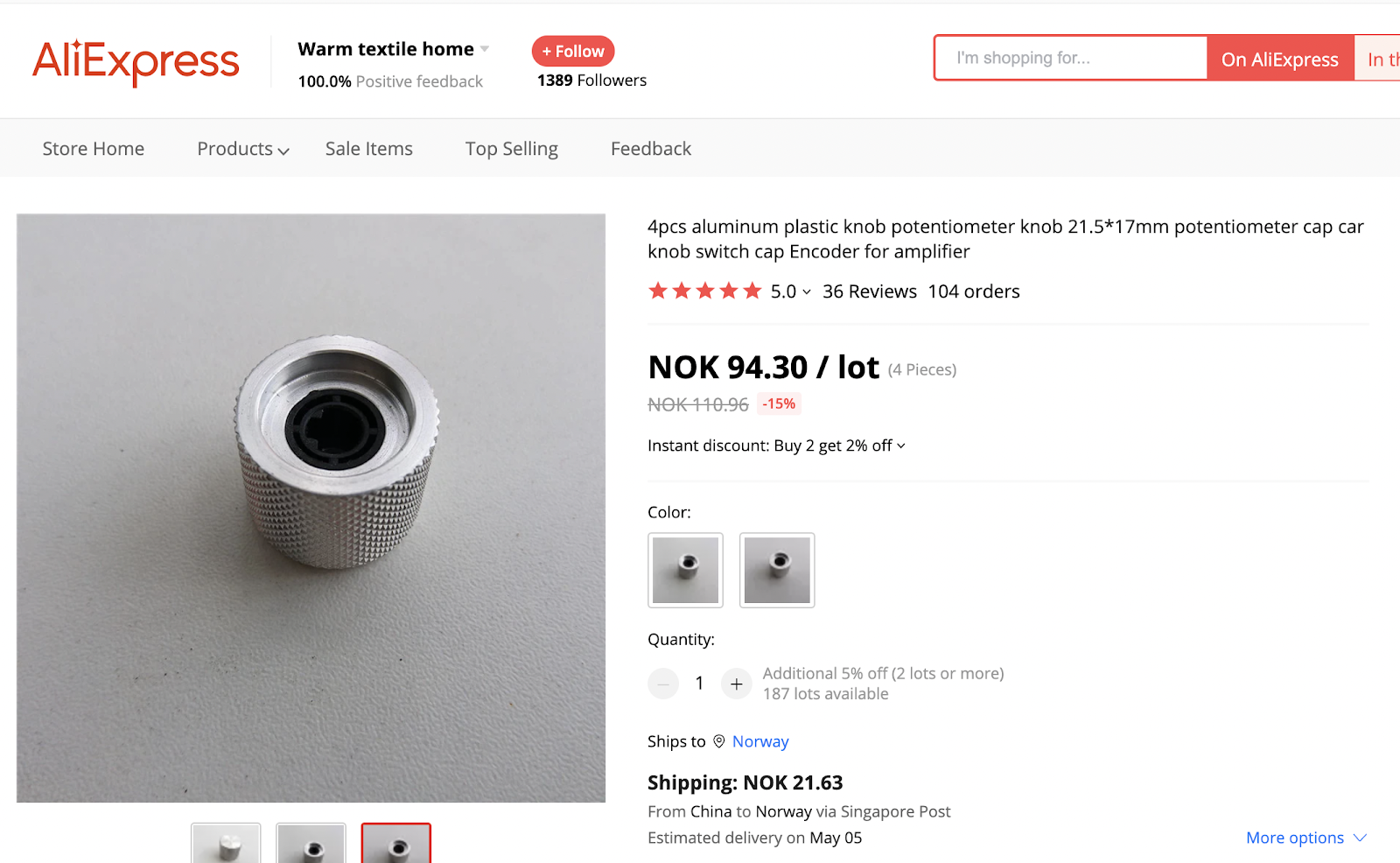

Massive aluminum knobs with D-shaft. I consider using these for the main rotary encoder but it depends on what I find for the other knobs. Update: I actually bought mine from Warm Textile Home, see below

These are round shaft but that's ok for single pots. I liked that they did not look as much guitar knob.

Warm Textile Home

https://www.aliexpress.com/item/32802055908.html

CW Switches Electric Store

Anyway, They have been super helpfull in finding alternatives. They say they can get me the one in the lower right corner with D-shaft. The MOQ is 500 and price $0.89 which is ok.

Then they suggested 15 x 17 D-axis:

I have also inquired about 10 x 16, 17 x 17 and 25 x 17, but that's where the dialogue stopped.

Shenzen Hengda Electronics

While not black, this is an honorable mention: A 24mm alu knob that may be a good alternative for the waveshaper/filter knobs. I have 10 of them.

https://www.aliexpress.com/item/1005003184444519.html

https://www.aliexpress.com/item/4001039507025.html

I reached out to Shenzen and they asked me for pics and details about what I need, but so far they haven't gotten back to me again.

Changshenghong

https://www.aliexpress.com/item/32873353173.html

Changshenghong has two sizes of pots that will go nicely with the ones above, though the 34mm one is a bit tall. Also, they are hideously expensive so I haven't bought any. I have not yet contacted Changshenghong ab out other variations.

HIFIw / HIFIvv / Hifi amplifier spare parts center

While not the same as the other knobs, they have some good looking knobs that MAY go well with my other guitar-ish knob:

https://www.aliexpress.com/item/32620216429.html

I've ordered a couple of these, possibly for the waveshape/filter knobs

SENGTERBELLE HIFI Audio World

https://www.aliexpress.com/item/32819963066.html

These look like smaller versions of the one above. They may be too small for me but I wanted to check them out anyway.

Other producers

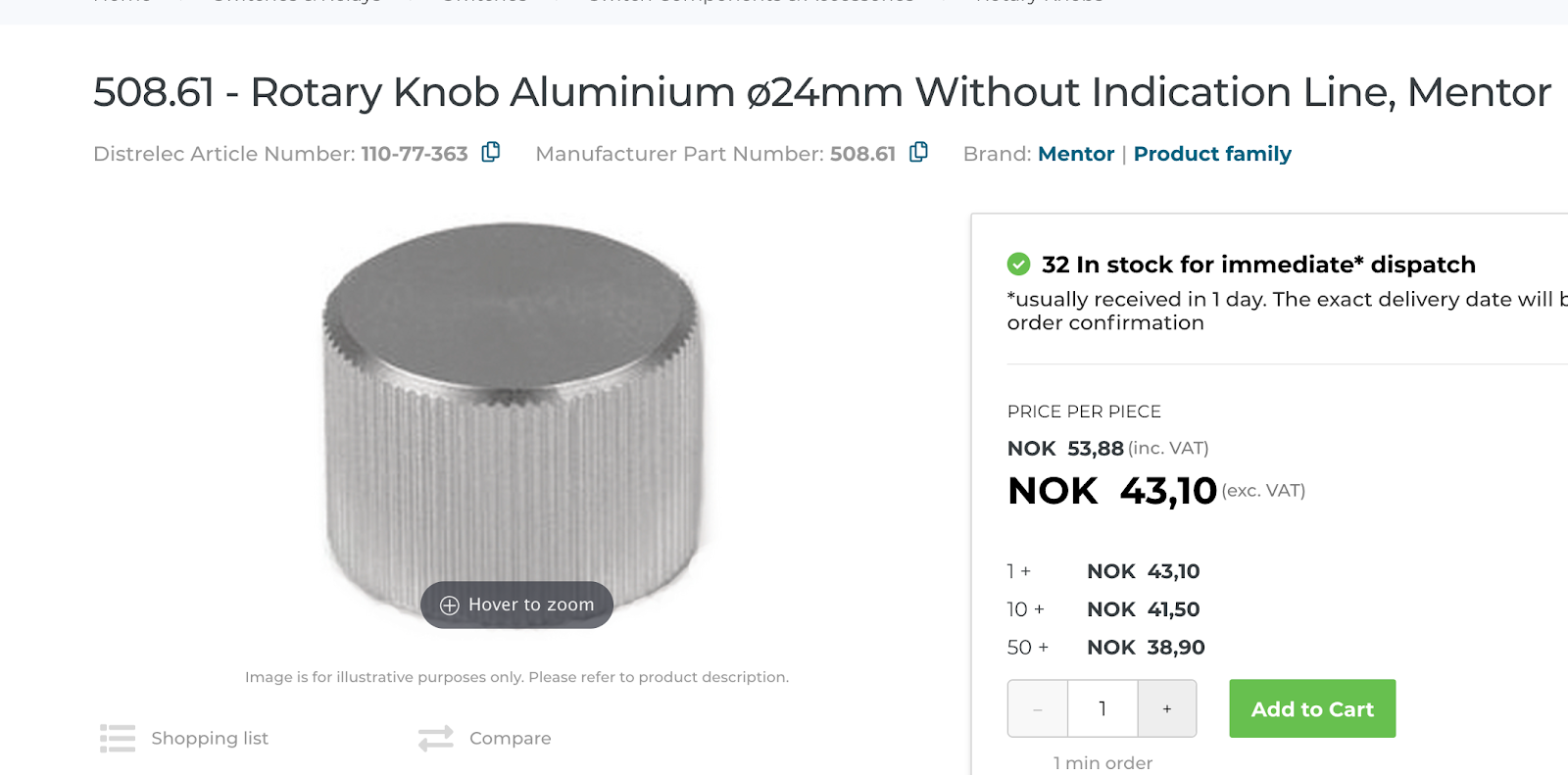

Mentor

https://www.mentor.de.com/bauelemente/en/portfolio-2/portfolio-knobs/

Mentor have a few series of good looking knobs. Some are available at Elfa and other vendors, even without pointer:

https://www.elfadistrelec.no/en/rotary-knob-without-line-aluminium-o30mm-mentor-513-61/p/11077374

They seem to be set-screw/round shaft versions.

DuPPa

Not sure how I stumbled upon this, but I found and ordered some cool variations of the guitar knob, this one fits an encoder with transparent shaft and RGB led:

https://www.duppa.net/shop/aluminum-black-knob-with-ring/

I hoped these would look better in real life but they are, especially the gray ones, a bit scruffy. Not TOO bad though. Since the center cap is black I think I would go with the all black ones, so lets see how it compares to the other black guitar-knob-ish ones I have coming.

I did however try the gray one on a black background, and the result is pretty good, better than expected. The pics do not do it justice though

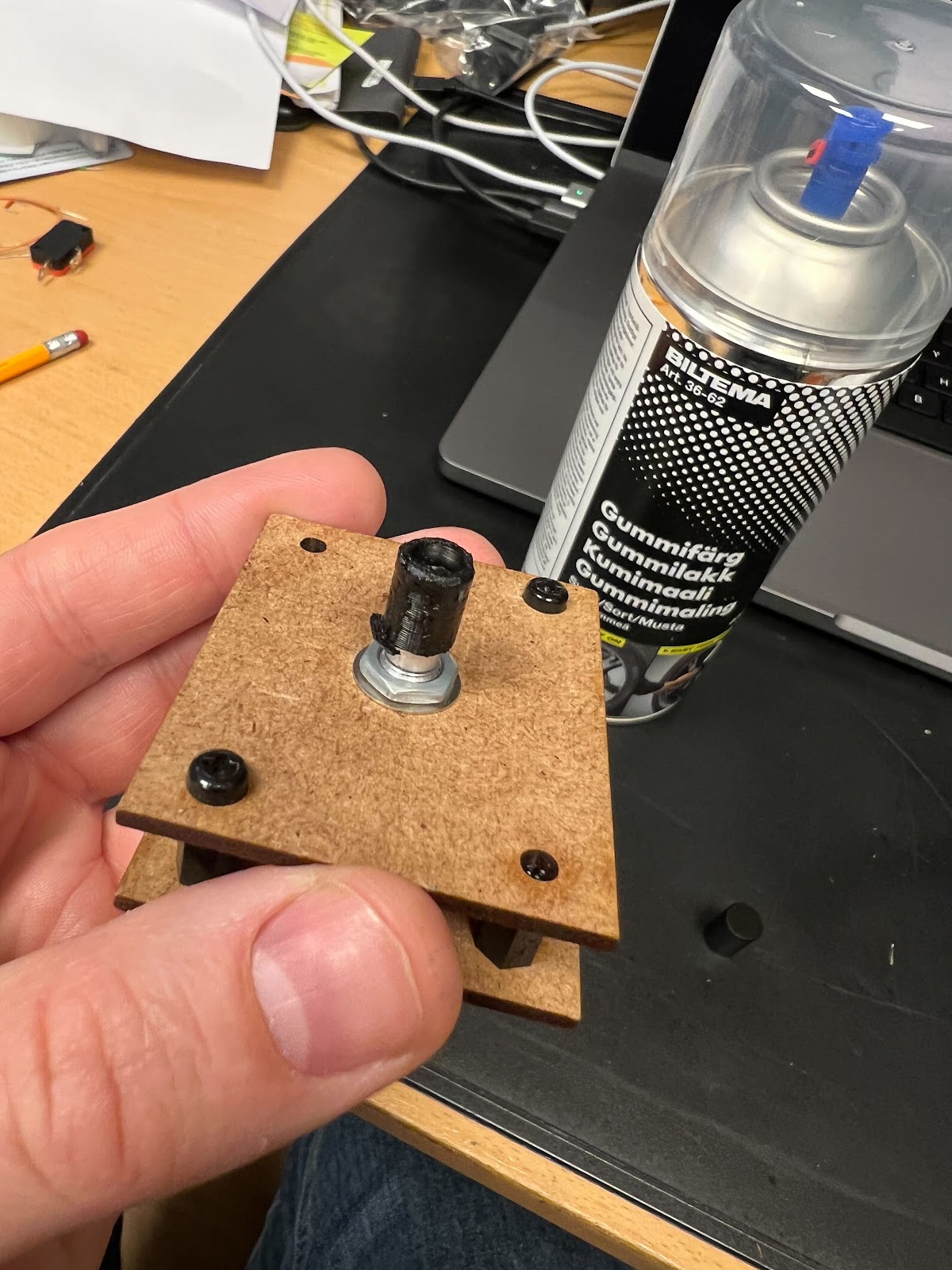

DIY

I posted a question about knobs on the Synth DIY list on facebook, and a friendly soul pointed out that I could have them CNC milled. He payed around 3 euros for the small ones, 4.5 for the middle and 5.5 for the big (in Sweden):

Final notes

PS: Here is my post about custom D-shaft insert for the 10mm pot: https://atosynth.blogspot.com/2021/03/from-33mm-square-to-d-shaft.html

The grip was actually so good that it pulled the insert out of the cap (it had not been glued). This also showed that the rubber spray leaked through the 3D print. After letting it dry i put the cap back on and now it sits firmly again.